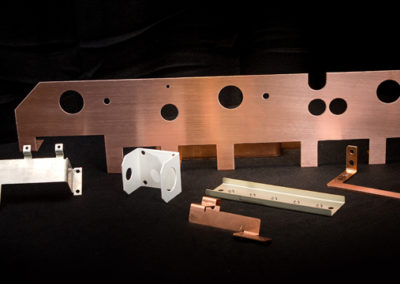

Sheet Metal Work Fabrication

– Customized low volume sheet metal production

– High quality sheet metal service

– Laser cutting/ stamping/ sending and different techniques available

Sheet Metal

At our sheet metal workshop we encompass bending, shearing, staking, laser, stamping, wire cutting, as well as CNC punching, CNC folding, drilling, tapping, countersinking and counterboring. Our craftsmen who care highly experienced have been manipulating sheet metal for years and come from a wide range of backgrounds.

Materials:

• Aluminum alloy

• Copper

• Stainless Steel

• Galvanized steel

• Zinc alloy

- Length and width

- Tolerance

- ≥400mm

- ±0.8mm

- Thickness

- Tolerance

- ≥0.5~1.5mm

- ±0.08mm

- >1.5~3.0mm

- ±0.17mm

- >3.0mm

- ±0.20mm

- Angle Tolerance: ±1.5 °

Why choose us?